Tiny Torquer: Mini motors, big dreams

- 13.05.2025

- News Study Program

A tight-knit community: group photo of the Tiny Torquers.

Find out how a new mini motorcycle racing class is being created at the University of Applied Sciences Kufstein Tirol – and why it's more than just a student project.

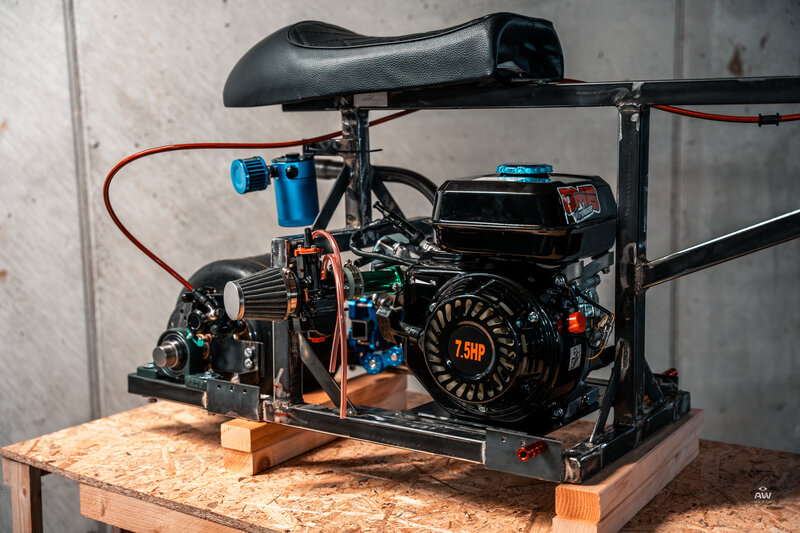

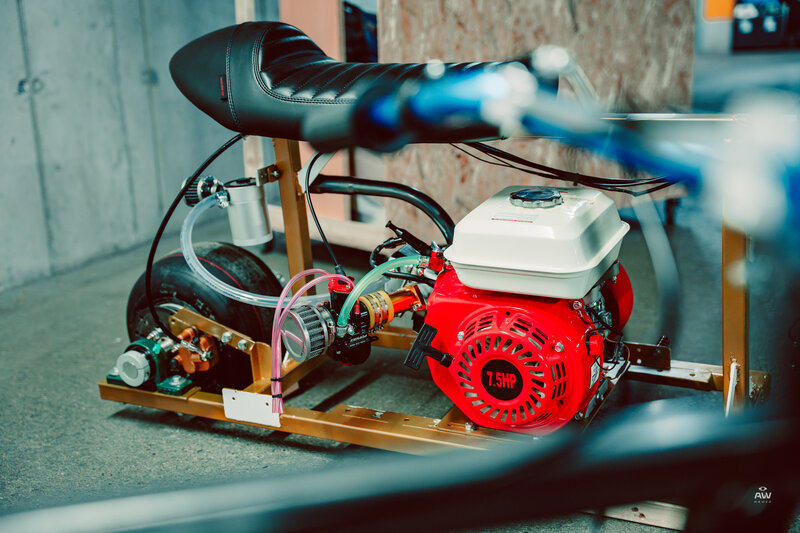

The smell of metal, oil, and burnt methanol hangs in the air. A wooden frame leans in a corner of the workshop, next to it a shiny, almost finished mini motorcycle stands in the semi-darkness. It is equipped with an engine that is actually used in lawnmowers. What initially appears unremarkable is part of a grand idea: Welcome to Tiny Torquern – a working group at the University of Applied Sciences Kufstein Tirol that operates as part of an association of the same name and is much more than just a fun hobby. It is a project that uniquely combines low-threshold motorsport, sustainability in practice, and modern engineering education.

SMALL MACHINES, BIG IMPACT

Not only are the motorcycles tiny, but the engines are also deliberately small, with a displacement of 200 cubic centimeters and a simple four-stroke design. “They are inexpensive, reliable, and ideal for learning,” says Prof. (FH) Dr. Christian Schmid, the initiator of the project and professor of product development in the industrial engineering degree program. Many components come from karting, and the frames are made of steel – making them 100 percent recyclable.

We want to show that technology does not have to be expensive and complicated.

Prof. (FH) Dr. Christian Schmid

Initiator of the project and professor of product development in the industrial engineering degree program

The components for the bikes cost between EUR 600,- and EUR 1.000,- – an entry point into motorsport that many can afford. “The project thrives on creativity and initiative – and that's exactly what we want to encourage.” Active in motorsport for more than 30 years, Schmid brings international experience from the US and has a clear plan: to make technology tangible, inspire enthusiasm, and show young people how they can create something with their own hands.

SCREW, LEARN, RIDE

What makes this project special is that the frames of the two-wheelers are not initially created on a screen, but out of wood. The students test the ergonomics, seating position, and usability in mock-ups. Only when everything fits is the welding done—in a specially constructed welding container. This saves material and time and helps to make the development process tangible.

Each of the mini bikes is unique.

The rules? Clear, but flexible. Standard motor (an inexpensive industrial motor), maximum tire size, specific dimensions – everything else is open. Creativity is expressly encouraged. The result is something unique made from inexpensive parts – kart wheels, industrial bearings – and it works: speeds of up to 120 km/h are possible on the eighth mile. The cars are driven in drag race mode. This means driving in a straight line; there are no curves. This is due to the design on the one hand, and safety considerations on the other. After all, the safety of the drivers is also a top priority for Schmid.

Schmid's project is now firmly established in the industrial engineering degree program. What began as a private initiative—in the Tiny Torquer association, which Schmid founded himself last November with like-minded people—is now an integral part of teaching. The students design, weld, and test. Each frame is unique, and each motor is modified. “They really build something here. They learn what works – and what doesn't,” says Schmid. It's not just about technology, but also about responsibility. Those who have designed their own mini bike will ride it with respect later on.

“The students not only learn technical basics, but also experience real product development,” explains Schmid. Mistakes are allowed – in fact, they are encouraged. ‘Fail fast and early’ is the motto.

IT'S A BALANCE TO daily STUDY LIFE. YOU'RE NOT JUST SITTING IN FRONT OF A SCREEN, YOU'RE ACTUALLY DOING SOMETHING WITH YOUR HANDS.

Matthias Hoffmann

Student with a background in motorsports

Together with his team, he opted for a curved tubular frame—significantly more complex than the usual square designs. “We improvised, bent, discarded, and rethought. It wasn't easy—but that's exactly what makes it special.”

Emilia Dora Arnold, who comes from near the Sachsenring, is also enthusiastic: “I want to work in motorsport later on. Here, I can really get started in the right direction—in a practical and inexpensive way.” She was surprised that you can build a working racing bike for less than €1,000. “Motorsport is often a question of money. We make it more accessible.”

Sustainability? Yes, please!

Sustainability also plays a major role, despite the combustion engines. “Our bikes consume hardly any fuel; we run on methanol, an alcohol that is not a fossil fuel,” explains Schmid. The frames are made of steel and are dismantled when the students leave the university. The individual parts are stored on shelves and reused in the next project. “We deliberately build them to be robust and repairable,” says Schmid. “That's more sustainable than many e-scooters.”

A master's project is currently working on a test bench to make the effects of engine modifications scientifically measurable. At the same time, a bachlor's thesis is comparing combustion engines and electric motors. “We are not a romantic old-timer club – but neither are we a technology-obsessed innovation circus. We think holistically,” says Schmid.

LEARN TECHNOLOGY, LIVE TEAM SPIRIT

For many, it is the team spirit that makes the project so special. Bernhard Mandl, research assistant in the field of ERP systems and business process management at the University of Applied Sciences Kufstein Tirol and treasurer of the association, sums it up: “We are not an association that just focuses on speed. For us, it's about building, tinkering together – and working together.”

Tiny Torquer chairman Prof. (FH) Dr. Christian Schmid and club treasurer Bernhard Mandl, MSc, with one of the bikes they built themselves.

And it works: students and teachers, bachelor's and master's students, beginners and motorsport enthusiasts work side by side here. New members, even those without a university background, are welcome – regardless of whether they have a technical background or are simply curious. “We even have people who just want to learn how to weld,” laughs Schmid. “And they are just as important.”

A MOVEMENT IN THE MAKING

The Tiny Torquer association, founded in Ebbs and now with over 20 members, is already planning its next steps. The first races in Germany have been organized, and talks with organizers are underway. The goal is to establish a separate class—with uniform rules but plenty of room for individuality. And: more visibility. “We need sponsors and test tracks—both of which are not easy to find,” says Schmid. But the response – including from the media – is growing. A social media presence is being set up and a YouTube channel is planned.

The project is a stroke of luck for the industrial engineering degree program. It shows that studying technology is not just about formulas and Excel spreadsheets. It's about creativity, teamwork, and real, tangible progress.

WHERE TO DRIVE?

One obstacle remains: suitable race tracks. Schmid and his team are encountering resistance in Tyrol, mainly for environmental reasons. According to Schmid, however, fuel consumption is minimal: “We're talking about 0.1 liters of methanol per 200 meters.” Alternative locations such as Bavaria or Vorarlberg are being considered, and in the long term, the aim is to organize their own events – for example, at St. Johann Airfield or at Glemseck 101, one of Europe's largest custom bike gatherings.

Learning by Doing

What makes this project special is that it has a ripple effect. Not only students at the university, but also companies in the region are showing interest—for example, in training their apprentices.

And so they continue to tinker, weld, and ride—not because it's part of a curriculum, but because they want to. The mini bikes are rolling. And maybe soon they'll be rolling on an official race track. Then it won't just be a cool project, but a movement with a future.

Links:

- Industrial Engineering & Management | ft

- tinytorquer_racing | Instagram

- www.tiny-torquer.com | Website

- tinytorquerracing@gmail.com | Kontakt